Automatic Weighing Bag Filling Machine Beans Feed Granular Fertilizer Pellet

Basic Info

| Model NO. | DCS-50-C |

| After-sales Service | Lifetime After-Sales |

| Warranty | 1 Year |

| Automatic Grade | Semi-Automatic |

| Application | Rice, Flour, Wood Pellet & Feed Pellet |

| Type | Filling and Sealing Machine |

| Forming Species | Bag Moulding |

| Forming Function | Filling |

| Driven Type | Electric |

| Material Type | Grain |

| Packaging | Bag |

| Packaging Material | Plastic |

| Voltage | as Clients Prime; Requirement to Customize |

| Power | 220V 50Hz |

| Bag | 0--50kg/Bag |

| Speed | 200-300 Bags /H |

| Sealing Type | Heat Sealer or Sewing |

| Air Source(MPa) | 0.4-0.8MPa |

| Belt Conveyor | 2.2m Long |

| Error | +/-0.2-0.5% |

| Electric Cabinet | CE Standard |

| Equip | Sewing Machine |

| Transport Package | EU Standard; HDF Package |

| Specification | Customizable Size |

| Trademark | YUFCHINA |

| Origin | China |

| HS Code | 8422303090 |

| Production Capacity | 50 Sets Per Month |

Product Description

Description of Packing Machine

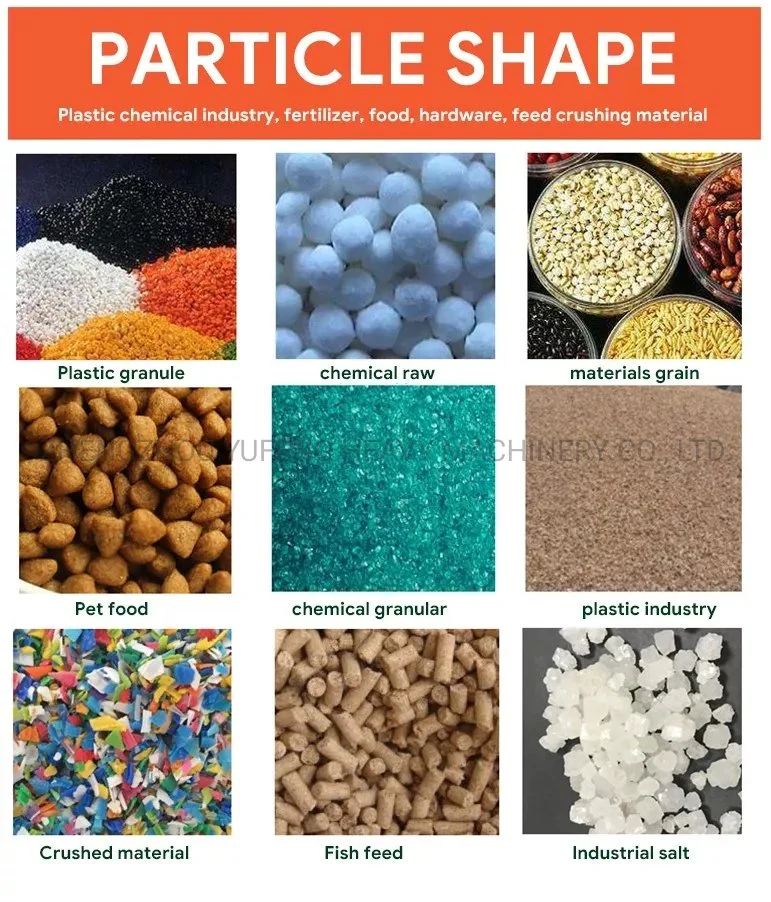

Particle packing machine, for granular, good fluidity materials designed by particle packing machine, it has a high weighing accuracy, easy to operate, reliable, fully functional and other characteristics, can be widely used in feed, food , food, seeds, metallurgy, pharmaceutical, petrochemical, non-metallic mineral, chemical, mineral, rubber, leather, fertilizer and other industries.Granular Quantitative Packing Machine is a kind of packaging equipment controlled by computer, which integrates digital quantitative, weighing and packaging.Widely used packaging machines highlights the features of multi-functional integration.

Features of Packing Machine

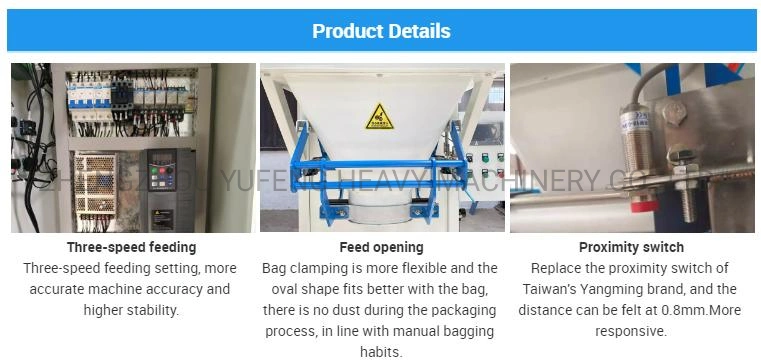

1. Take three speeds feeding to guarantee the precision at min weight and the speed at max weight 2. The head of bag stitching machine, conveyor, and hot sealing machine can rise and fall. Also, the system is applied to sealing and convey with max and min bags. 3. There is shock-absorbing device in weighing system; It could avoid the shock of other devices through floor and tube to affect the weighing system. 4. Good seal in system, and it has dust catcher and aspirator. 5. Guide groves in conveyor roller and guide bars in conveyor belts to avoid excursion and cracks.

Application of Packing Machine

Mainly applicable to: quantitative packaging of grains, fertilizers, chemicals and other granular materials.It has the characteristics of automatic weighing, time-saving and labor-saving, simple structure, convenient operation, high work efficiency, firmness, good stability, accurate weighing and high sensitivity.Rubber Granule Packaging Machine can be divided into large package and small package. They are suitable for quantitative packaging of rubber granules, plastic granules, fertilizer granules, feed granules, chemical granules, grain granules, building materials granules, and metal granules.

Parameter of Packing Machine

Model | DCS-50-C |

Operation Speed | 300-420 bags/h |

Weighing Range | 20-50 kg |

Scale Interval | 10g |

Accuracy Grade | ±30g |

Powder Consumption | 4N AC380V 50Hz 1.3KW |

Air Consumption | 0.4~0.6 Mpa 1.5m3/h |

Machine height | 3500mm |

Function of Packing Machine

1. There is detecting device in system. 2. Processes function of automatic modifying drop height.3. Processes function of self-test, error pilot and fault code indication. 4. With the serial interfere to communicate the computer.5. With five-figure password to control the accumulator in system.6. Pre-set filling number in system.

SALES AND SERVICE

Pre-sales service1.Tailor-made efficient technical solutions for you.2.Tell us your needs, we will recommend the machine to you, professionally introduce the machine3.Service consultation in 365 days a year.4.24 hours to respond to messages in a timely manner service During the project1.Standardized precision production of production orders in 8 major departments.2. The operation of the machine will be tested before delivery, video will be given to the customer, and the machine will bechecked and accepted3.The entire production process is visualized, which is convenient to check the production progress at any time.4.The idling machine test is combined with the feeder test - strict quality inspection.After-sale service1. Accepting service consultation in 365 days a year.2. Our after-sales engineer can come at any time for maintenance.3. We will return customers on a regular basis, to ensure proper operation of the production line.4. We provide accessories for all equipment.

CUSTOMER CASE

Very welcome your consultation!