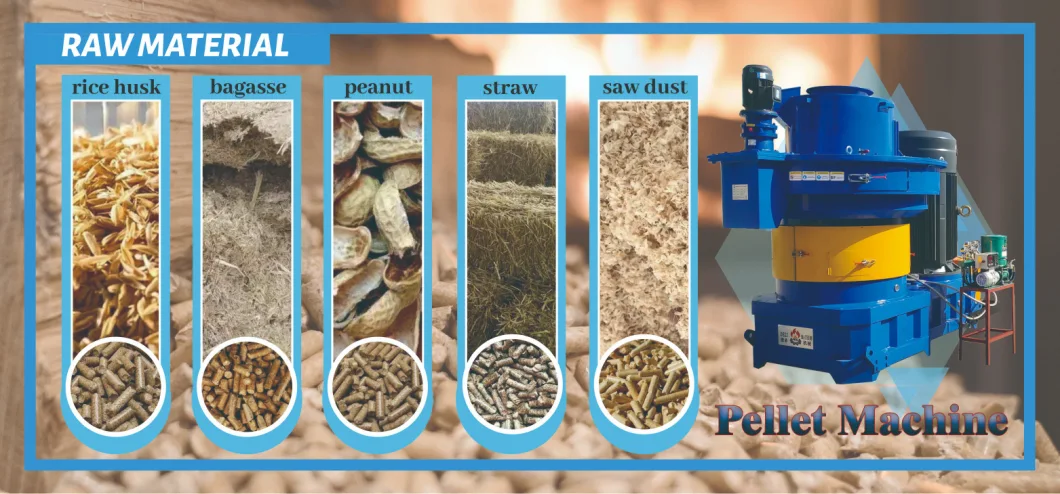

Vertical Ring Die Industrial Large Scale Engineering Biomass Fuel Hard Wood Sawdust Rice Peanut Coconut Bagasse Straw Hay Complete Best Pellet Mill for Sale

Basic Info

| Model NO. | XGJ850P |

| Type | Vertical Ring Die Pellet Machine |

| Voltage | Customized |

| Automatic Grade | Automatic |

| Controlling Mode | Artificial |

| Energy Saving | Energy Saving |

| Certification | CE |

| Warranty | 3 Years |

| Customized | Customized |

| Condition | New |

| Color | Multi Color |

| After-sales Service | Whole Working Lifetime |

| Pellets Density | 110-1400kgs/ M³ |

| Weight of Machine | 13500 Kgs |

| Number of Rollers (PCS) | 3 Sets of Big Rollers Inside |

| Spare Parts | Die and Roller |

| Power | 220kw |

| Capaciry | 2.5-3.5t |

| Colour | Can Be Customized |

| Service Time | 24 Hours |

| Transport Package | Bulk in Container |

| Specification | 2650*1850*2100mm |

| Trademark | DEXI |

| Origin | China |

| HS Code | 84793000 |

| Production Capacity | 30 Sets/Month |

Packaging & Delivery

Package size per unit product 265.00cm * 185.00cm * 210.00cm Gross weight per unit product 13500.000kgProduct Description

Vertical Ring Die Industrial Large Scale Engineering Biomass Fuel Hard Wood Sawdust Rice Peanut Coconut Bagasse Straw Hay Complete Best Pellet Mill for SaleProduct Description

In the video is our ring die pellet machine, the model of this machine is 220kw-XGJ-850P,it's output capacity is 2500-3500kgs/hour, the pellet diameter can be 6 mm, or 8 mm by change ring die.XGJ850P wood pellet maker machine is mainly using for press different kind of biomass materials into cylinder shape pellets, the output pellets is good green fuel energy for fireplace or industry biomass burner. XGJ series CE certificate wood pellet machine is our main product which has adopted the essence of pellet mill in oversea market.

1. Famous Motor:

The motor is a famous brand motor with a three-year warranty.2.Big&Stable Gearbox: In the gearbox, the transmission is stable, low noise , the service life is long, and it can withstand high power and heavy load.3. Gear Oil Lubrication Pump&Motor: The gearbox has its own lubrication and cooling system, which can cool down the lubricating oil without stopping the machine to ensure long-term operation.4. Feeder Hopper: This design can avoid the raw material be stuck in pelletizing chamber.5. Pelletizing Chamber Inside: The pelletizing chamber inside including the double layer ring die which made of astainless steel and the roller assembly,these two parts have the following characters: Particular design, reasonable structure, low energy, high efficiency, long life and so on.6.Radiator: Cooling the oil which inside the big gearboxMachine's Advantages:

1.XGJ850P wood pellet mill is update version of XGJ850, the machine with big strong industry gearbox, make the motor and machine shaft directly connected with the gearbox, improve the transmission efficiency, make the machine stronger and more stable.

2.The ring die is made of double-layer stainless steel.

3.the motor is a famous brand motor with a three-year warranty.

4.This wood pellet maker with totally automatically lubrication system, the gearbox with lubrication pump let the gear oil cycle lubrication of each bearing and gear.5.And there also another grease pump regularly inject grease to the roller bearing.

Mainly Parameter of machines:

| Model | Power (kw) | wood pellets Capacity (kgs/h) | Weight of the machine(kgs) | Dimension of the machine (mm) |

| XGJ560P | 90+1.5+0.75+0.55+2.2 | 1000-1500 | 4200 | 2600x1300x2300 |

| XGJ560P | 132+1.5+0.75+0.55+2.2 | 1500-2000 | 5400 | 2600x1250x1600 |

| XGJ700P | 160+1.5+0.75+0.55+2.2 | 2000-2500 | 6800 | 2600x1400x2100 |

| XGJ850 | 220+3+0.75+0.55+3 | 2000-3000 | 9600 | 2600x1600x1950 |

| XGJ850P | 220+3+0.75+0.55+3 | 2500-3500 | 13500 | 2650×1850×2100 |

| XGJ850P | 250+3+0.75+0.55+3 | 3000-4500 | 15000 | 2750×1850×2100 |

Wood pellet mill is mainly applicable for difficult molding materials with low adhesion rate, for example, hard wood sawdust, rice husk, sunflower husk, peanut shell and fruit shell; branch, stem, bark and other wood waste; a variety of crop stalks; rubber, cement, ash and other chemical materials.When working, material from feeding mouth vertically to the roller frame board surface, through the rotation of the roller frame board, continuous uniform within the mold cavity surface. (the surface for roller connected ring die), under the roller rolling powder material through the die hole (Uniformly distributed in the inner surface of die).This process is the role of material under high pressure, high temperature, produce a physical change or proper chemical changes(depends on different kind of raw materials ), make the powder material form elongated cylindrical solid body, the cylindrical solid elongation continuously will be cutting by uniformly distributed around the mold cutting knifes, become to "pellets" the pellet pusher will collecting the pellets to the outlet place. (Product structure chart) Pellets under the action of gravity automatic fall, this pellet making process is complete.

Shandong Dexi Machine is professional supplier for the biomass pellet machines and complete pellet production line. our products involve , wood chipper, wood sawdust making machine, hammer mill, drum rotary dryer, pellet making machine, pellet cooling machine, pellet packing machine and other related auxiliary equipment.

We also provide design, technology supports, machine inspection service, etc. Cooperating with different manufacturers and research centers, we provide the pellet making machines with outstanding quality. We have a group of experienced experts and outstanding engineers who do provide the professional service delivery and installation. Based on the client's specific requirement, we also accept customize design and machine producing order. Through the years established good working relationship with some reputable organizations both at home and abroad with outstanding goodwill.

Any interesting for the wood pellet making machines, please feel free to contact us.