Hot Selling Flat/Ring Die Cotton Stalk Biomass Sawdust Wood Feed Pellet Granulator Pellet Making Machine Price 6-8 mm Wood Pellet Mill 500 Kg/H 1-10 Tons

Basic Info

| Model NO. | 450VR 560VR 600VR 700VR |

| Controlling Mode | Button |

| Energy Saving | Energy Saving |

| Certification | CE, SGS |

| Warranty | 2 Years |

| Customized | Non-Customized |

| Condition | New |

| Color | Multi Color |

| After-sales Service | Video Support |

| Reducer | Tongli Brand |

| Function | to Make Wood Pellet for Fuel |

| Raw Materials | Sawdust, Wood Shavings, Wood Log |

| Name | Wood Pellet Machine Wood Pellet Mill |

| Transport Package | Wooden Case Packaging |

| Specification | 6mm 8mm |

| Trademark | Zhongdebao & Eternalwin |

| Origin | China |

| HS Code | 8479300000 |

| Production Capacity | 0.5-10 T/H |

Packaging & Delivery

Package size per unit product 500.00cm * 300.00cm * 400.00cm Gross weight per unit product 6000.000kgProduct Description

Product Description

Hot Selling Flat/Ring Die Cotton Stalk Biomass Sawdust Wood Feed Pellet Granulator Pellet Making Machine Price 6-8 mm Wood Pellet Mill 500 Kg/H 1-10 Tons

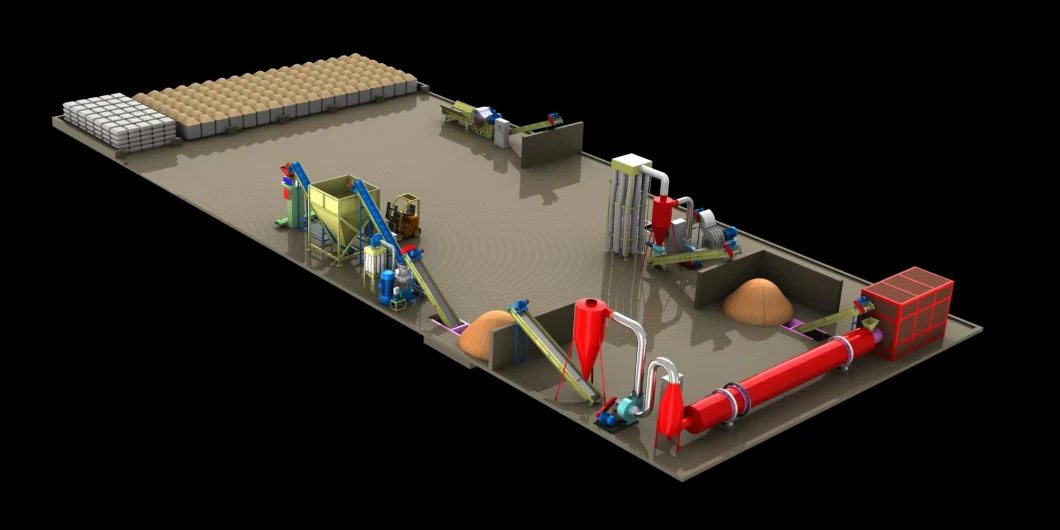

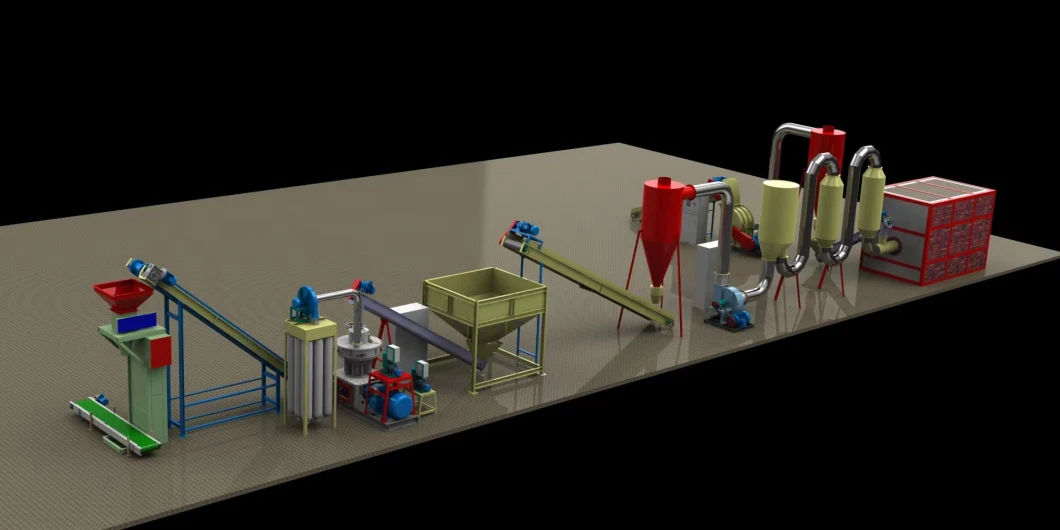

Wood pellet production lines include wood grinder, dryers, wood pelletizer and other machines.The wood pellet machine is a biomass new energy device. The wood granules are made of eucalyptus, birch, poplar, fruit wood, bamboo chips and crop straws, and the finished wood chips are produced by pulverization, drying, screening, granulation, cooling, packaging and the like. Its finished products are used in biomass power generation, boilers, fireplaces, etc.

| Crushing system | Cutter Grinder | |||

| Drying system | ||||

| Granulation system | Screw Feeder, Stock Bin, Feeder, Pellet Machine | |||

| Cooling system | Trommel Screen | |||

| Conveyor packaging | Conveyor, Packing Machine | |||

| Electronic control system | Electrical Control Cabinet | |||

Detailed Photos

color can be customized

300R pellet machine wood

420R moving roller wood log sawdust pellet mill

300A diesel engine type biomass wood pellet mill

We supply both wood pellet and FEED PELLET mill production line, capacity from 500kg/hour to 30 tons per hour.

Application

This system wood pellet mill is suitable for making different kind of material such as sawdust, rice husk, paddy straw, sunflower stalk,hulls, forestry wastes into wood pellets etc. It has been installed with the KAF gear reducer and electrical control box. It also can make the corn, oil cake for the feed stuff, which it could be feed pellets for the fish, chicken, animal, etc.pellet making machine wood pellet machines for sale press pellet wood pellet making machine.

Customer feedback

Our wood pellet mill machine sawdust pellet production line got a lot good feedback from customers all over the world.

Certifications

our wood pellet machines are CE approved, SGS verified.

Choose us, the machine quality is assured, and the business is in safe.

Our factory

Packaging & Shipping

Packing: standard export wooden case packing

Delivery time: 7-45 days after receipt of paymentPayment term: 30% deposit and balance before shipment.