Sand Silica Rotary Dryer

Basic Info

| Model NO. | 1.0*10, 1.2*12, 1.5*15, 1.8*18, 2.2*18, 3.0*25 |

| After-sales Service | 24hours |

| Warranty | 2 Years |

| Movement Way | Rotary |

| Atomization | Pressure Atomization |

| Flow | Cross Flow |

| Heating Mode | Gas Coal |

| Material Status | Powder, Solution |

| Drying Medium | Inactive Gas, Superheated Steam, Effluent Gas, Air |

| Operation Pressure | Atmospheric Pressure |

| Operational Method | Intermittent |

| Drying Material | Sand, Sawdust, Ore, Sludge, Manure, etc. |

| Drying Capacity | 0.5-150t/H |

| Heating Fuel | Coal, Wood, Gas, Oil, etc. |

| Delivery Time | 20-40 Days |

| Installation | Engineer Guide at Site |

| Transport Package | Suitable for ocean shipping |

| Specification | ISO9001: 2000 |

| Trademark | HONGJI |

| Origin | CHINA |

| HS Code | 8419399 |

| Production Capacity | 100 sets/month |

Product Description

Product Description

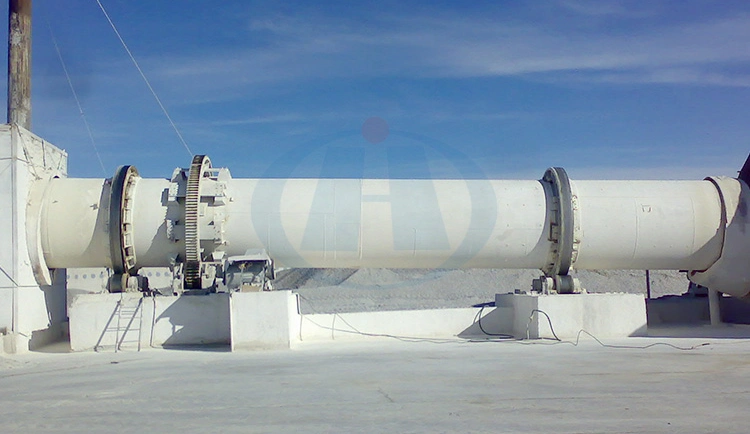

INTRUDUCTION FOR ROTARY DRYER

| Brief Introduction | Rotary dryer is widely used to dry materials in industries like cement, mine, construction, chemical, food, compound fertilizer, etc. Thermocouples are installed in feeding and discharging units to control temperature. Temperature change of the dryer also can be indicated by the thermometer, which is convenient for temperature control inside the dryer ( it is usually 250-350ºC). |

Applications | Powder & particle: Sands, limestone, stones, clay, mineral filter cake, coal, iron sulphate, filter cakes, fly ash, gypsum etc.Damp and sticky material: Coal slime, sewage sludge, bentonite, Kaolin etc.Corrosive material: Distillers 'grains, Fertilizer, animal dung, slag etc.Biomass material: Sawdust, wood chips etc. |

Features | 1.International standard with ISO, CE certificate. |

2.Simple system, safe and easy operation. | |

3.Flexibility in fuels used (NG, Oil, Coal ect.). | |

4.Year of experience with all types of dryers. | |

5.Capable of installation anywhere in world. | |

6.In house engineering for custom fit applications. | |

7.Proven design. |

Detailed Photos

Point 1-Steel Plate Selection

Chemical analysis was carried out on the material inspection, according to the requirements of GB700-2006, dryer drum thickness < = 20 mm we use Q245 - A, > 20 mm we use Q245 - B; According to the GB/T 2970-2004 class ii, the range of 60 mm weld edge every board before cutting for ultrasonic flaw detection.

Point 1-Steel Plate Selection Chemical analysis was carried out on the material inspection, according to the requirements of GB700-2006, dryer drum thickness < = 20 mm we use Q245 - A, > 20 mm we use Q245 - B; According to the GB/T 2970-2004 class ii, the range of 60 mm weld edge every board before cutting for ultrasonic flaw detection. |

Point 3-nspectionExamination all the parts according to the drawing after processing completion. Spraying primer, rust preventing paint, and heat resistance paint.

Rotary Dryer Structure

Product Parameters

Packaging & Shipping

Success Case

Company Profile

Certifications