Industrial Bagasse Coffee Grounds Olive Pomace Rotary Drum Dryer, Fruit Residues, Bean Dregs, Sugar Beet Pulp Rotary Dryer Machine

Basic Info

| Drying Medium | Air |

| Operation Pressure | Atmospheric Pressure |

| Operational Method | Continuous |

| Application | Biomass Fuel, Animal Feeds |

| Power | 34-155kw |

| Weight | 22t-76t |

| Input Capacity | 1.53-12.14 T/H |

| Output Capacity | 1.08-8.57 T/H |

| Vaporization | 0.45-3.57 T/H |

| Early Moisture | 35%-45% |

| Final Moisture | 15% (Adjustable) |

| Temperature | 250-310 |

| Transport Package | Container |

| Specification | 22t-76t |

| Trademark | jiutian |

| Origin | Henan, China |

| HS Code | 8419399090 |

| Production Capacity | 20 Sets/Month |

Product Description

Biomass Waste Rotary DryerProduct Description

The pomace dryer can be used for pomace (apple pomace, tomato pomace, pear pomace, etc.), monosodium glutamate protein, beet pulp, starch residue, corn dregs, citric acid tail liquid, feed, protein powder, beet pulp , bean dregs, distiller's grains, dregs and other materials drying work.

Working Principle

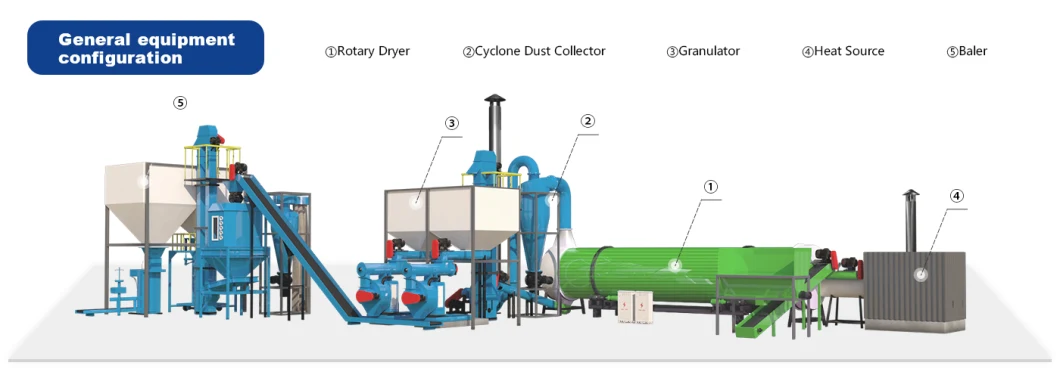

The pomace dryer is mainly composed of a heat source, a feeder, a feeder, a rotary drum, a discharger, an induced draft fan, a discharger and a power distribution cabinet. After the dehydrated wet material is added to the dryer, the material is evenly dispersed in the dryer and fully contacted with the hot air under the turning of the plate copying device evenly distributed in the drum, which accelerates the drying heat and mass transfer. During the drying process, under the action of the inclined plate and hot air, the material is discharged to the star-shaped discharge valve in the other section of the dryer to discharge the finished product.We have different heat sources. For example, direct heating model hot blast stove, indirect hot blast stove, heat conduction oil, electric heating, steam, etc.

Product Features

1. PLC smart control & high automaticity. The performance of the rotary dryer and moisture content of dry materials is automatically controlled in stable states.

2. High heat efficiency. The design of multiple circumferential flights combination and flow rate adjustment devices ensure the control of drying period and temperature distribution. The effect of insulation is as high as 70% and raise heat efficiency by 20%.

3. Four-wheel drive, more steady and stable.

4. Save 50% space compared with traditional dryers and reduce 50% civil investment.

5. Convenient variable frequency control systems. The customer could change the material flow rate and product moisture based on their need.

6. Environmental and safe. Modular configuration of dust collection and purification systems

7. More choice for novel air furnace with high efficiency, convenient manipulation, and energy control, which could reduce 30% energy cost and 20% electric cost.

Product Parameters

| Model(JTSG) | 1406 | 1615 | 2008/3 | 2010/3 | 2210/3 | 2510/3 | 2512/3 | 2912/3 |

| Input Capacity(t/h) | 1.53 | 2.89 | 5.2 | 6.63 | 7.24 | 8.91 | 10.5 | 12.14 |

| Output Capacity(t/h) | 1.08 | 2.03 | 3.67 | 4.68 | 5.11 | 6.29 | 7.41 | 8.57 |

| Vaporization(t/h) | 0.45 | 0.85 | 1.53 | 1.95 | 2.13 | 2.62 | 3.09 | 3.57 |

| Early Moisture(%) | 40±5% | |||||||

| Final Moisture(%) | 15% | |||||||

| Drying Temperature(ºC) | 280±30ºC | |||||||

| Total Power(kw) | 34 | 45 | 78 | 90 | 105 | 125 | 140 | 155 |

| Total Weight(t) | 22 | 28 | 40 | 45 | 50 | 60 | 68 | 76 |

| Plant Area(m) | 5*15 | 6*22 | 8*16 | 8*18 | 8*20 | 10*20 | 10*24 | 10*24 |

Packaging & Shipping

Your device will be packed well in container and suit for long ocean shipping.

FAQ

Q: What is your Business Model? Trading company or factory?

A: We are a 18 years factory, all our machinery is manufactured by ourselves, factory direct sales, product quality, and after-sales service can be guaranteed.

Q: Can I visit your factory?

A: Yes. Many domestic and international customers visit our factory every year. Our company is located in Zhengzhou Henan province, China, you can come here by air or train.

The nearest airport is Zhengzhou Xinzheng International Airport, and the Airport Code is CGO.

We will pick you up at the airport. Welcome to visit our factory.

Q: What is the Quality of your products?

A: Zhengzhou Jiutian products come with the best quality, and our products passed CE certification, exported to lots countries around the world, such as Australia, Malaysia, India, Italy, Indonesia, Vietnam, Philippines, Korea, Brazil, Argentina, Russia, South Africa, etc. You can rest assured of the quality absolutely.

Q: How long is the Warranty of your equipment?

A: Our warranty period is one year generally.

Company Profile

Founded in 2003, Zhengzhou Jiutian is an enterprise with 200 employees committed to enhancing clients productively, profitability, and safety. Jiutian has developed more than 200 patented products for the drying machine.Jiutian Machinery products include biomass drying and pelletizing production line, feed dregs drying equipment, coal drying upgrading equipment, poultry manure drying equipment, coconut fiber, and coir drying machine, and related wood shaving machine, pellet machine, dehydration machine, carbonization furnace, etc. At present, Jiutian not only has a huge customer resource system and considerable market share in the country but also in the UK, Russia, Greece, Italy, Israel, Morocco, Congo, Cte d'Ivoire, Madagascar, Australia, India, Vietnam, Laos, Indonesia, Malaysia, Sri Lanka, Chile, the United States, and other countries have established a case of dryers and successfully put into production, to achieve the quality and technology of dryer products and international standards.