Biomass Fuel Rotary Drum Dryer for Crops Stalks, Paddy Straw, Bamboo Chips, Sawdust, Bagasse, Olive Pomace, Palm Shell Industrial Wood Chip Dryer

Basic Info

| Drying Medium | Air |

| Operation Pressure | Atmospheric Pressure |

| Operational Method | Continuous |

| Application | Animal Feeds, Biomass Fuel |

| Daily Capacity(T/D) | 62.5-120 |

| Evaporation Capacity(T/H) | 1.35-2.5 |

| Initial Moisture(%) | 60 |

| Final Moisture(%) | 12-15% (Adjustable) |

| Total Installed Power(Kw) | 78-135 |

| Total Weight(Kg) | 25000-43500 |

| Transport Package | Container |

| Specification | 25t-80t |

| Origin | Henan, China |

| HS Code | 8419399090 |

| Production Capacity | 20 Sets/Month |

Product Description

Product Description

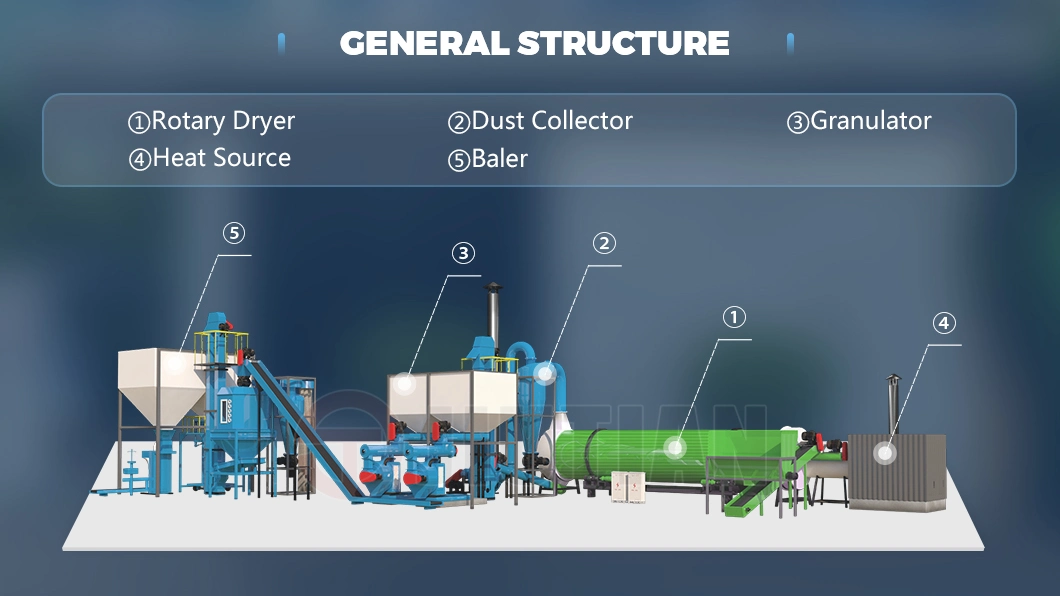

Biomass rotary dryer is suitable for wood chips, sawdust, bamboo chips, wood shavings, shavings, barley straw, oat straw, wheat straw, rye straw, rice straw, sorghum straw, corn straw, potato vines, bean stems Drying of stalks, drying of peanut vines, bagasse, olive pomace, coffee grounds and other materials with a moisture content of 35-65%. According to the characteristics of each biomass material, output size, application requirements, cost control, degree of automation, and on-site working conditions, the drying and molding process technology is optimized.

Heat Source Device:

1. Steam waste heat heating: equipped with automatic chain furnace, high and low coal injection furnace, and other coal-fired hot blast stoves, the cost of coal-fired drying is low, but coal-fired pollution is serious. Therefore, in addition to improving the heating efficiency of coal-fired hot blast stoves and drums In addition to the heat utilization rate of the dryer, the dust removal and purification system is equipped with dry secondary dust removal, dry and wet secondary dust removal, dry and wet multi-stage dust removal and other dust removal equipment, so as to ensure that the coal-fired drying equipment passes the EIA;2. Gas and oil heating: mainly use the waste heat of boiler plants, power plants, steam, or heat transfer oil, etc., to perform technical treatment on the steam through the tubular reformer to meet the drying heat and temperature requirements, and the steam temperature is required to be 110 above degree;3. Coal-fired heat supply: natural gas burners, gas generators, fuel-fired engines, etc. are used to build combustion chambers, with sufficient heat supply, sufficient combustion, and greater optimization of fuel consumption.

Product Features

1. It can realize intelligent control, one-key 'fool' operation, automatic adjustment of operating parameters, and the dryer is always running in the best state to ensure that the moisture of the dried wood chips is uniform and stable, which is more energy-saving than traditional dryers.2. Automatically remove impurities and iron to ensure that the impurities of the baked wood chips do not enter the subsequent process.3. The thermal efficiency of the self-insulation of the cylinder is as high as 70% (the thermal efficiency of the traditional single-cylinder dryer is only 35%), and the thermal efficiency is increased by more than 30%.4. Using four-wheel drive, the transmission is more stable and reliable.5. Reduce the land occupation by about 50%, and reduce the civil construction investment by about 50%.6. The internal structure of the dryer adopts a variety of high-efficiency lifting plate combination modes, which can effectively control the drying process and heat distribution. The heat utilization rate is high, and the exhaust gas discharge temperature is lower than 50 °C.7. Using variable frequency speed regulation to control the material flow, the final moisture index can be easily adjusted according to user needs.8. Modular dust collection, dedusting, purification, heat recovery and utilization configuration, safe and environmentally friendly.9. Equipped with a variety of new energy-saving hot blast stoves, which are efficient and energy-saving, have controllable heating, simple to operate, reduce energy consumption by about 30%, reduce power consumption by 20%, and lower operating costs.

Working Principle

The material flow is: the material with moisture content of about 35-65% enters the inner layer of the rotary drum from the feeding device to realize downstream drying. It moves to the other end of the inner layer and enters the middle layer for countercurrent drying. The material is continuously and repeatedly raised in the middle layer, in a two-step forward and one-step backward mode. The material in the middle layer not only fully absorbs the heat emitted by the inner layer drum, but also absorbs The heat of the middle drum also prolongs the drying time, and the material reaches the best drying state here. The material travels to the other end of the middle layer and falls into the outer layer. The material travels in a rectangular multi-loop way in the outer drum. The material that achieves the drying effect quickly travels and exits the drum under the action of hot air. The wet material that does not achieve the drying effect cannot be quickly due to its own weight. The material is fully dried in this rectangular copy board, the drying process is completed, and the material is discharged by the screw conveyor. A shock cleaning device is installed inside the drum to prevent the material from sticking to the drum wall.The gas flow is: the air is pressurized by the hot blast stove blower and enters the hot blast stove for combustion and heating, and the temperature reaches 550-600 ºC. When the temperature is lowered to 55-60 ºC, it is discharged from the dryer, and the dust-laden moisture is collected by the cyclone dust collector, and the wet dust collector is purified and discharged up to the standard.

Product Parameters

| Model | Daily Capacity(t/d) | Evaporation Capacity(t/h) | Initial Moisture(%) | Final Moisture(%) | Drying Temperature(ºC) | Total Installed Power(kw) | Total Weight(kg) | Cover Area (m²) |

| JTSG2010/3 | 62.5 | 1.35 | 60±5 | 12-15% (Adjustable) | 250±30ºC | 78 | 25000 | 8m×18m |

| JTSG2210/3 | 70.5 | 1.44 | 85 | 27000 | 8m×18m | |||

| JTSG2510/3 | 83.5 | 1.76 | 110 | 35000 | 10m×18m | |||

| JTSG2512/3 | 108.0 | 2.10 | 125 | 38000 | 10m×22m | |||

| JTSG2912/3 | 120.0 | 2.50 | 135 | 43500 | 10m×25m |

Successful Cases

Zhengzhou Jiutian Machinery Equipment dryer products cover all kinds of drying machine products such as dregs, biomass, organic fertilizer, sludge, yeast, coconut fiber and chaff, and coal slime. At present, the company not only has a huge customer resource system and considerable market share in the country but also in the UK, Russia, Greece, Italy, Israel, Morocco, Congo, Egypt, Côte d'Ivoire, Madagascar, Australia, India, Vietnam, Laos, Indonesia, Malaysia. In many overseas countries such as Sri Lanka, Chile, and the United States, the dryer case was established and successfully put into operation, and the quality and technology of the dryer products were in line with international standards.

If you want to see more details and videos, please contact us!Company Profile

Founded in 2003, Zhengzhou Jiutian is an enterprise with 200 employees committed to enhancing clients productively, profitability, and safety. Jiutian has developed more than 200 patented products for the drying machine. Jiutian Machinery products include biomass drying and pelletizing production line, feed dregs drying equipment, coal drying upgrading equipment, poultry manure drying equipment, coconut fiber, and coir drying machine, and related wood shaving machine, pellet machine, dehydration machine, carbonization furnace, etc. At present, Jiutian not only has a huge customer resource system and considerable market share in the country but also in the UK, Russia, Greece, Italy, Israel, Morocco, Congo, Cte d'Ivoire, Madagascar, Australia, India, Vietnam, Laos, Indonesia, Malaysia, Sri Lanka, Chile, the United States, and other countries have established a case of dryers and successfully put into production, to achieve the quality and technology of dryer products and international standards.

Related Products