5tph-10tph Mining Rotary Drum Dryer for Silica Sand, Clay, Kaolin, Bentonite, Clinker, Nickel, River Sand Drying Machine

Basic Info

| Model NO. | DD |

| Warranty | One Year |

| Color | Customized |

| Customized | Customized |

| Condition | New |

| After-sales Service | Online Support, Field Installation |

| Capacity(River Sand) | 4-100t/H |

| Capacity(Fly Ash) | 2-60t/H |

| Capacity(Slag) | 3-90t/H |

| Length | 2-8.5m |

| Diameter | 2-4.2m |

| Coal Consumption | 6-12kg(Drying 1t Materials) |

| Total Power | 5.5-18.5X4kw |

| Transport Package | Standard Package |

| Trademark | DONGDING |

| Origin | China |

| HS Code | 8419399090 |

| Production Capacity | 20 Sets Per Month |

Product Description

Sand Rotary Dryer Introduction

Sand dryer is a three drum drying equipment for processing a large number of materials. It is generally suitable for drying granular materials, especially for drying sand, river sand and quartz sand with excellent drying effect. Due to the reliable operation, simple operation, strong adaptability, large processing capacity, energy conservation and environmental protection, the rotary sand dryer is widely used in building materials, chemical industry, casting, wall insulation and other industries.

Sand Rotary Dryer Main Features1. The inner part of the sand dryer is made of wear-resistant manganese plate, which is 3-4 times more wear-resistant than ordinary steel plate.2. Compared with the traditional single drum dryer, the thermal efficiency is increased by more than 40%.3. The floor area is small, which is about 60% less than that of single drum dryer, and the geotechnical investment is reduced by 60%.4. There is no air leakage phenomenon, and the sealing difficulty is completely solved.5. The discharge temperature is less than 60 ºC, it can be directly fed into the warehouse without cooling.6. The initial moisture content of the material is 15%, and the final moisture content after drying is less than 0.5-1%, which is the first choice for drying engineering such as dry and wet mortar production line.

Sand Rotary Dryer Application

The rotary dryer is suitable for sand drying, such as mineral sand, quartz sand, river sand, yellow sand, sea sand, pomegranate sand, machine-made sand, dry powder mortar, water slag, mountain sand, weathered sand, etc. It is widely used in many industries such as construction, building materials, casting, smelting, chemical, cement, medicine and minerals.

Sand Dryer Working Principle

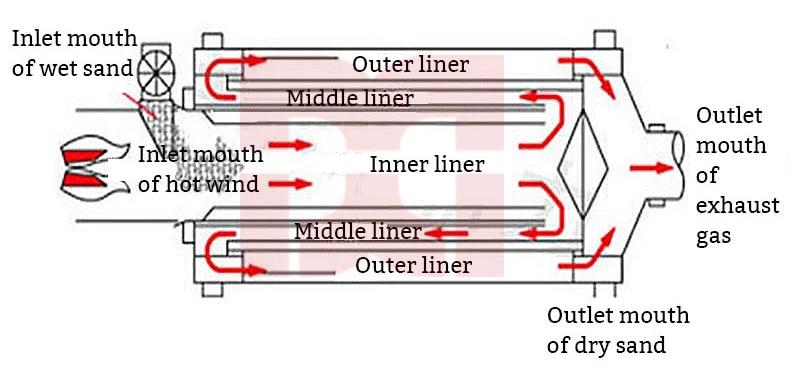

The raw material, sand, is conveyed to the inner cylinder by the feeder continuously and evenly , and is thrown and pushed forward by the spiral lifting board. In addition, it is dispersed by the intermediate dispersing device to form a curtain which fully contacts with the heat. The water evaporates rapidly then led out induced draft fan. Semi-dry material enters the middle cylinder and outer cylinder, and then fully contacts with the heat finally enters the discharge bin after meeting the final drying requirements.

Product Parameters

| Model | Capacity(T/h) | Coal consumption (drying 1t materials)kg | Total power | ||

| River sand | Fly ash | Slag | |||

| Φ2.0×2 | 4-5 | 2-3 | 3-5 | 12-14 | 5.5kw |

| Φ2.0×4 | 8-12 | 4-6 | 8-10 | 12-14 | 3kw×2 |

| Φ2.0×5 | 12-15 | 6-7 | 10-13 | 10-12 | 4kw×2 |

| Φ2.2×4.5 | 14-18 | 7-9 | 12-15 | 10-12 | 5.5kw×2 |

| Φ2.5×6 | 23-28 | 10-13 | 20-22 | 10-12 | 5.5kw×4 |

| Φ2.8×6 | 30-35 | 15-18 | 25-30 | 10-12 | 5.5kw×4 |

| Φ3.0×6 | 35-40 | 18-20 | 32-35 | 8-10 | 7.5kw×4 |

| Φ3.0×7 | 40-45 | 20-25 | 35-40 | 8-10 | 7.5kw×4 |

| Φ3.2×7 | 45-50 | 25-30 | 40-45 | 8-10 | 11kw×4 |

| Φ3.2×8 | 50-55 | 30-35 | 45-50 | 8-10 | 11kw×4 |

| Φ3.6×8 | 60-70 | 35-40 | 60-65 | 6-8 | 15kw×4 |

| Φ3.8×9 | 70-80 | 40-45 | 70-75 | 6-8 | 15kw×4 |

| Φ4.0×10 | 90-100 | 45-50 | 80-90 | 6-8 | 18.5kw×4 |

| Φ4.2×8.5 | 80-100 | 45-60 | 80-90 | 6-8 | 18.5kw×4 |

| (The moisture is :15%~1%) | |||||

Detailed Pictures

Company Profile

Zhengzhou Dongding Machinery is a high-tech enterprise integrating R&D design, production installation, production management, sales, after-sales service and technical consultation.We have core technology system, which integrates the thermal combustion, dehydration, drying, molding, separation and dust removal. Scientific equipment selection and technical process optimization are adopted according to different material characteristics. Currently our equipment has been successfully applied in the coal, feed, biomass fuel, organic fertilizer processing industries. Especially the coal dryers like lignite coal dryer, coal ash dryer, raw coal rotary dryer, coal slime dryer, etc. are well received by the customers at home and abroad.* More than ten years of experience in R&D and manufacturing of drying equipment* Equipped with multi-stage dust removal and purification system to reduce pollution* One - to - one customized production solution to reduce equipment budget* Our customers are located in more than 60 countries and regions around the world.

Customer Visit

At present, our products have been recognized by customers in China and all over the world, and successfully exported to Indonesia, South Africa, Vietnam, Thailand, Myanmar, India, Egypt and other countries and regions.

Certifications