Industrial Mining Rotary Dryers Limestone, Clay, Sand, Water Slag, Coal Slime, Sludge, Fly Ash, Gypsum Powder, Rock, Petroleum Coke Drum Dryer Drying Machine

Basic Info

| Atomization | Rotary Atomization |

| Flow | Cross Flow |

| Heating Mode | Transmission |

| Material Status | Powder, Bulk |

| Drying Medium | Air |

| Operation Pressure | Atmospheric Pressure |

| Operational Method | Continuous |

| Product Name | Mining Dryer |

| Power(Kw) | 120-500 |

| Capacity | 300-2000t/D |

| Spatial Footprint (M) | 8*26-15*50 |

| Material | Steel, Stainless Steel |

| Transport Package | Standard Package |

| Trademark | jiutian |

| Origin | Henan, China |

| HS Code | 8419399090 |

| Production Capacity | 20 Sets/Month |

Packaging & Delivery

Package size per unit product 200.00cm * 200.00cm * 200.00cm Gross weight per unit product 9000.000kgProduct Description

Product Description

Industrial Slag Dryer IntroductionSlag dryer is widely used in building materials, metallurgy, mineral processing, chemical industry, cement and other industries, and can be used to dry slag, calcium carbide slag, limestone, clay, river sand, quartz sand, water slag and other materials. The slag dryer is suitable for a variety of combustion furnaces: high temperature boiling furnace, coal grinding pulverizing furnace and artificial coal stoking furnace.The current industrial slag tumble dryer is divided into two processes: high temperature hot air drying and low temperature steam drying. The former is called direct heating tumble dryer, which uses gas, fuel oil, coal-fired, mixed fuel, biomass fuel, etc. as heat sources. The hot blast stove provides heat and outputs the necessary heat and temperature to meet the needs of rapid drying of wet materials; the latter is a tube bundle type tumble dryer for indirect low-temperature drying, which is mainly used for steam waste heat from power plants, boiler plants and other units. Fast drying of wet materials. The current industrial dryer integrates environmental protection technologies such as clean fuel, multi-stage dry and wet dust removal, fully sealed drying structure, and enhanced thermal insulation layer.

Working Principle

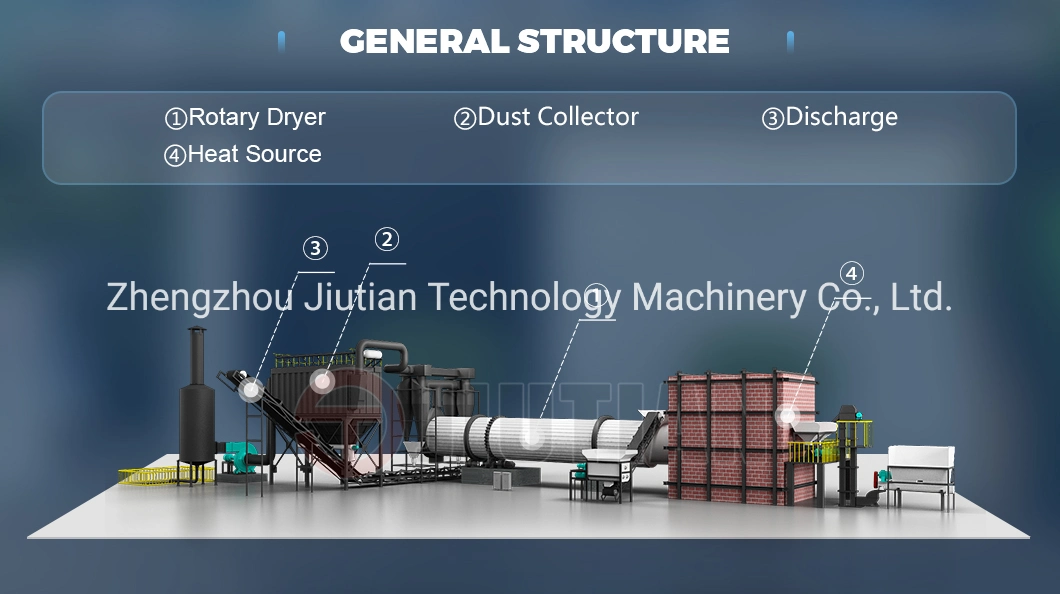

The mineral slag tumble dryer is mainly composed of a hot blast stove, a belt feeder, a tumble dryer, a belt discharger, an induced draft fan, a cyclone, a bag filter (or a wet filter) and an operation control system. constitute.

The equipment adopts a co-current (or counter-current) drying process. Its working principle is as follows. After the wet material enters the drying drum, it is divided into the following working areas:1. In the material guide area, the mineral slag enters this area and contacts with the high temperature hot air to quickly evaporate the water, and the material is guided into the next work area under the guide plate with large lead angle;2. In the plate copying area, the ore slag is picked up by the plate in this area to form a material curtain state. At this time, the material is fully contacted with the hot air, and the moisture in the ore slag is rapidly evaporated and stripped into water vapor, and the water vapor is drawn by the induced draft fan. In this area, the ore slag is dried to a loose state with a moisture content of less than 5% (or lower), and after heat exchange, the material reaches the required moisture state and enters the final outlet. material area;3. In the discharge area, the drum does not have a copy plate in this area, and the material rolls and slides to the discharge port in this area to complete the entire drying process.

Product Features

1. The ore slag constant speed quantitative feeder solves the feeding uniformity in the dryer, and overcomes the previous problems of intermittent feeding, material blocking, and large instantaneous material volume, which is the premise to improve the evaporation intensity.(1) The unique buffer silo and feeding mechanism are designed to overcome the intermittent feeding or the sudden big and small problems caused by uneven feeding;(2) A large inclination unpowered screw propeller is set at the feeding end of the drum, which not only evenly sends the incoming ore slag into the drum drying section, but also further cuts and breaks up the large pieces of ore slag;2. Optimizing the design of the internal structure of the dryer to maximize the heat exchange area between the material and the hot air quality is the basis for improving the evaporation intensity.(1) Continuously optimize the design of the internal structure layout of the drum and the lifting plate, and finally finalize the unique structure of the inner lifting plate of the drum and the mixed section layout of different functions. Maximize the heat exchange area between the ore slag and the hot air, so that the water in the slag can quickly heat up, evaporate, and be taken away by the hot air;(2) The original patented technology of layered drying of rotary drum dryer. According to the law of the heating speed and traveling speed of the materials with different sizes and particle sizes in the drum, a multi-component layer drying device is set up, and the small grate is placed in a large grate to control the pulverization of the small particle material due to excessive drying and the different heating inside and outside the large particle material. Uneven drying phenomenon to ensure drying uniformity.3. Reasonably select the type of hot blast stove, optimize its internal structure design and masonry quality, reduce the air leakage rate, reduce the oxygen content in the hot air to less than 5%, and adjust the temperature point of any process requirements at 700-1100 °C, which is the dryer Providing a homogeneous and stable heat source is a reliable guarantee for the high-intensity operation of the slag dryer.4. The measurement and control technology system adopts computer operation platform and frequency conversion PLC control technology, and the process parameters such as temperature, pressure, oxygen concentration, equipment speed and other process parameters are interlocked and controlled online to realize automatic detection and control of the entire system, with centralized and local switching functions to ensure The system operates stably with the largest output, the best quality, the most energy-saving mode, and safe explosion-proof operation.5. Optimize the configuration of gravity sedimentation + cyclone dust collector + wet/bag type dust collector three-stage dust collection and dust removal equipment, dust concentration <30mg/Nm3, to ensure that the exhaust gas is discharged up to standard.6. The first modular design, manufacturing, transportation, installation, service concept and assembly and test machine platform, to return customers with more optimized design and manufacturing, more convenient transportation and installation services, and ensure maximum customer benefits.7. Solve the problem of water vapor returning to the material after the temperature of the system decreases during the co-directional movement caused by the downstream dehumidification of the traditional dryer, improve the drying efficiency, and achieve the purpose of deep dehydration.8. The dryer adopts the double sealing mode of fish scale or labyrinth, expandable graphite packing type mechanical seal, to ensure the safe operation of the dryer system with closed oxygen.

Applications

Rotary drum dryer is mainly used to dry block, powdered, paste-type materials or materials with large water content. Cylinder dryer can dry materials like ore, sand, slag, coal, clay, sludge, coal slurry, hematite, copper, kaolin, slag, graphite, gypsum, ceramics, calcium carbonate, bauxite, tailings, etc.

Product Parameters

| Equipment | Output (T/D) | Moisture content of raw material (%) | Final moisture content (%) | Total Power (kw) | Spatial footprint (m) |

| JTHG1916 | 300 | 20-30 | <5 | 120 | 8*26 |

| JTHG2218 | 500 | 20-30 | <5 | 160 | 10*35 |

| JTHG2520 | 700 | 20-30 | <5 | 200 | 10*40 |

| JTHG2820 | 1000 | 20-30 | <5 | 290 | 12*40 |

| JTHG3430 | 1500 | 20-30 | <5 | 420 | 15*46 |

| JTHG4032 | 2000 | 20-30 | <5 | 500 | 15*50 |

| Note: The production capacity of the equipment is directly related to the proportion of mineral slag to reduce the moisture, the precipitation ratio is large, and the equipment production capacity is reduced accordingly. Specific consulting firm. | |||||

Company Profile

Founded in 2003, Zhengzhou Jiutian is an enterprise with 200 employees committed to enhancing clients productively, profitability, and safety. Jiutian has developed more than 200 patented products for the drying machine. Jiutian Machinery products include biomass drying and pelletizing production line, feed dregs drying equipment, coal drying upgrading equipment, poultry manure drying equipment, coconut fiber, and coir drying machine, and related wood shaving machine, pellet machine, dehydration machine, carbonization furnace, etc.

At present, Jiutian not only has a huge customer resource system and considerable market share in the country but also in the UK, Russia, Greece, Italy, Israel, Morocco, Congo, Côte d'Ivoire, Madagascar, Australia, India, Vietnam, Laos, Indonesia, Malaysia, Sri Lanka. In Chile, the United States and other countries have established a case of dryers and successfully put them into production, to achieve the quality and technology of dryer products and international standards.

Successful Cases