Romania 1-2t/H Biomass Spruce Wood Pellet Making Machine Beech Flat Die Roller Sawdust Wood Pellet Machine Manufacture Eucaly Pellet Line Wood Pellet Mill

Basic Info

| Model NO. | LH-420 wood pellet mill |

| Controlling Mode | Artificial |

| Energy Saving | Energy Saving |

| Certification | CE |

| Warranty | 1 Year |

| Customized | Customized |

| Condition | New |

| Color | Green |

| After-sales Service | Online Technical Parameter Support |

| Capacity | 1500-2000kgs/H Wood Pellet Machine |

| Heating Value | 4500-4700 Kcal |

| Total Rated Power | 197.45 Kw / H for Pellet Line |

| Worker | 2 Persons |

| Working Shop | 21m Length X 6m Width X 6m Heigth |

| Raw Materials | Logs, Waste Wood, Rice Husk, Wood Chips |

| Diameter of Pellets | 6mm, 8mm Wood Pellets |

| Moisture of Pellets | Less Than 8% |

| Exporting Certification | CE Wood Pellet Making Line |

| Solid Biomass Fuel | Cooking, Electricity Power, Heating |

| Transport Package | 1 - 3 * 40′hq Containers |

| Specification | CE, SGS, BV |

| Trademark | LEABON |

| Origin | China, Shandong |

| HS Code | 84748020 |

| Production Capacity | 100 Sets/Month |

Packaging & Delivery

Package size per unit product 130.00cm * 110.00cm * 180.00cm Gross weight per unit product 2500.000kgProduct Description

Bulgaria Use 1-2t/H Hard Biomass Wood Pellet Making Machine Beech Sawdust Wood Pellet Machine Price Wood Pellet MillProduct DescriptionProduction Flow Chart of Wood Pellet Production Line :

raw material for making fuel pellet can be:wood, logs, waste wood, wood chips, sawdust, straw, rice husk, spruce shavings, furniture waste wood, sawmill plant sawdust.Size: 3-5mm;Moisture content:10-15%Pellet diameteR:6/8/10/12mmPellelt Length:Adjustable Certification: CE Certification

Wood pellet making line is the process of making waste materials into solid fuel. The objects are used for burning purposes.

Complete Wood Pellet Production Line includes:

| 1 | Wood Splitter | Processing big size wood into smaller size. |

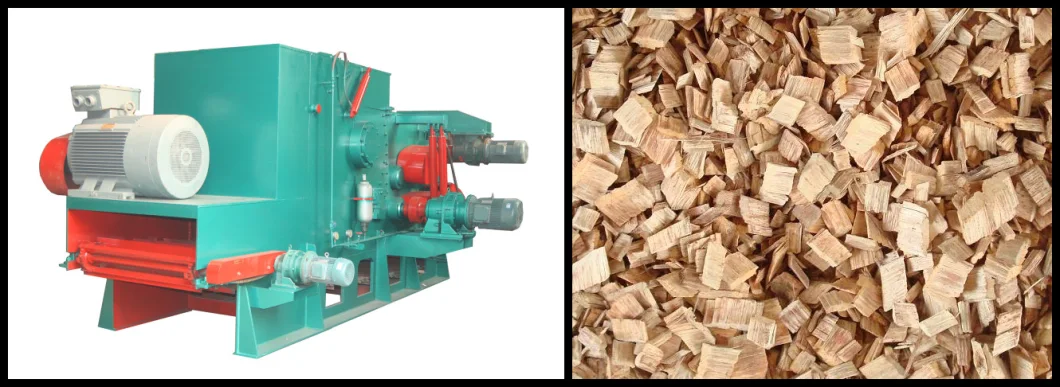

| 2 | Wood Chipper | Used to processing round wood logs into wood chips |

| 3 | Hammer Mill | Used to crushing wood chips to sawdust with 3-5mm size. |

| 4 | Dryer | Drying wet wood sawdust, reduce the humidity of sawdust to 10-15% from 30-40% |

| 5 | Wood Pellet Machine | Makin dried sawdust into wood pellet with 6/8//10mm diameter. |

| 6 | Cooler & Screening Machine | Cooling hot wood pellet, screening the dust out of wood pellet, keep pellets cleaning. |

| 7 | Packing Machine | Packaging wood pellets into bag, convenient for storage, sale and transportation. |

| 8 | Electric Control System | Control all machines of complete wood pellet production line at producion site. |

2). Crushing Process:

1) removing the barks from fresh logs, decrease the ash content of wood pellets;2) crushing the logs, waste wood, wood branch, wood bark into wood chips with 1mm thickness, 10mm length e wood chips into wooddust with 5mm screen.

3). Drying Process:

1) raw materials: wet wood dust;2) dried wood dust: 10-15% moisture;3) furnace: full carbon steel materials, 250-550 degree temperature;4) capacity: adjustable.

3).Pelletizing Process:

1) raw mterials requirement: moisture : 10-15%; size: 5mm screen for 6mm wood pellets;2) working performance: ring die: vertical ring die, 1500hours working life; transmission mode: gear transmission, 5years life; feeding process: uniformly inputing materals. rollers: 4 pcs , high working pressure, wide range of wood .3). Technical parameter of wood pellet machine:

4). Cooling&Screening Process:

1) hot wood pellet from pellet machine: about 80 degree, soft & easy-crack;2) after cooling, the pellet is close to room temperature, and very hard.

5). Packing Process:

1) .Package weight:15-25kgs/bag;2) Hheat sealing or seam.

Complete Wood Pellet Line:

Successfully Case of Complete Wood Pellet Production Line1). 350-1000kg/h Wood Pellet Making Line (350kg/h; 400-500kg/h; 600-800kg/h; 1000kg/h)

2). 2-10T/H Complete Wood Pellet Production Plant ( 1.5T/H; 2T/H; 3T/H; 4-5T/H; 10T/H )

Packaging & Shipping

Delivery of Wood Pellet Production Line by 1*40HQ Container

After Sales ServiceOur Service:

FAQFAQ:

If you are interested in wood pellet making line, please first kindly tell several needful information as follows:

| (1). What capacity would your prefer? -----The Capacity Range of Wood Pellet Machine: 0.5T/H; 0.8-1T/H; 1.5-2T/H; 2-3T; 3-4T/H. |

| (2). What is your raw material? -----According to different raw material(such as hard wood, soft wood, straw, rice hust), capacity is different. |

| (3). What is your raw material size? -----Best size for pressing high quality pellets is 3mm-5mm. |

| (4). What is the moisture of your raw material? -----Better to be 10-15%. ( If large than this, then we will recommend your Dryer Machine) |

| (5). Final Pellets Size? -----We have Diameter for Pellets: 6mm, 8mm, 10mm, 12mm.------Pellets Length: Adjustable20-50mm. (Normally our clients ask pellets length of 33mm, between 30-36mm) |

Pls Click "SEND" ask for more Catalog & EXW Price for wood pellet milll wood pellet machine wood pellet production line