Ribbon Industrial Powder Mixer Powder Mixing Machine Ribbon Blender

Basic Info

| Model NO. | 500L |

| Layout Type | Horizontal |

| Mixing Drum Shape | Drum |

| Additional Capabilities | Milling |

| Operating type | Continuous Operating |

| Condition | New |

| Speed | 23-33 Rpm |

| Plate Thickness | 4-8mm |

| Contact Material | SS304 Stainless Steel |

| Loading Factor | 0.6 |

| Shaft Type | One Shaft |

| Blade Type | Double Ribbon Blade |

| Transport Package | Plywood Packaging |

| Specification | 1000L |

| Trademark | KEDA |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 5000 Sets/ Year |

Product Description

Horizontal Ribbon Mixer

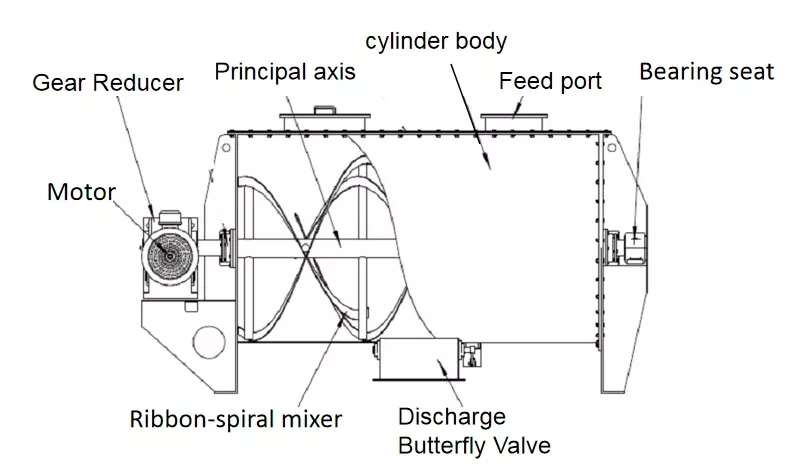

Ribbon mixer is designed for dry materials mixing, meantime liquid streams can be added. This mixer is composed of U-shaped cylinder, double helical ribbon blade and transmission parts. In working condition, the outer ribbon pushes materials from two sides to the middle, while the inner ribbon pushes materials from the middle to both sides. Through continuous convective circulation, the materials are sheared and mixed thoroughly and quickly. Batch cycle time shorten due to high mixing efficiency.

Application:

Dry Powder, Putty, Modified Corn Starch, Real Stone Paint, Chemical, Food, Animal feed, Pharmaceutical, Fertilizer, Plastic, Battery, Cosmetic.

Models:500L~10000L are available

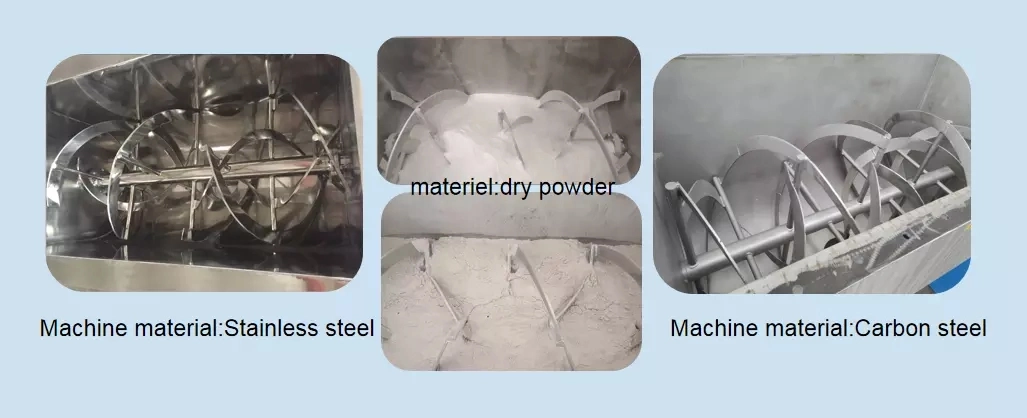

Fabricating Materials: SS304, SS316L, Carbon steel/MS

Heating/cooling jacket optional

Discharging Outlet: Bottom or Side

Customized machine is available.

Features:1. Solid stainless frame body extra stong for ruged use,2. Pneumatic Auto Discharger,3. Fast Open Folio Lid4. Curved Bottom Flip Board Valve, no dead angleTechnical Parameters Of Horizontal Mixer

| Model | 500L | 1000L | 1500L | 2000L | 3000L | 4000L | 5000L | 6000L | 8000L | 10000L |

Volume(L) | 500 | 1000 | 1500 | 2000 | 3000 | 4000 | 5000 | 6000 | 8000 | 10000 |

| Loading Factor | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Motor Power (KW) | 5.5 | 7.5 | 11 | 15 | 18.5 | 22 | 30 | 37 | 45 | 55 |

Gearbox Model | BWD2 | BWD3 | ZLY160 | ZLY180 | ZLY200 | ZLY200 | ZLY224 | ZLY224 | ZLY250 | ZLY280 |

| Speed (r/min) | 41 | 33 | 33 | 33 | 33 | 27 | 27 | 27 | 23 | 23 |

| Dimension L*W*H(m) | 1.9/0.7/1.4 | 3.0/0.8/1.5 | 3.2/1.35/1.6 | 3.3/1.4/1.7 | 3.5/1.5/1.7 | 3.6/1.4/1.7 | 3.7/1.6/1.7 | 3.8/1.7/1.8 | 4.5/1.8/1.9 | 4.8/2.0/2.1 |

| Plate thickness mm | 4 | 4 | 5 | 6 | 6 | 8 | 8 | 8 | 8 | 8 |

| Contact Material | SUS304 ( other material carbon steel, SUS201, SUS316L is available) | |||||||||

Usually with oil film wiredrawing polishing , mirror polishing price is more expensive. | ||||||||||

Working Principle

The horizontal ribbon mixer is under the action of the internal and external ribbons on the stirring shaft to turn the materials within the scope of the barrel. The inner spiral belt pushes the material from the middle to the sides of the cylinder, and the outer spiral belt pushes the material from the sides of the cylinder to the center. Convection circulation. Due to the agitation of the above movement, the materials are quickly and evenly mixed in a short time, so it is a high-efficiency mixing device with wide application, strong adaptability and good effect

ApplicationHorizontal ribbon mixer is widely used in chemical, battery materials , paints, dyes , pesticides , pharmaceuticals , food, feed ,additives , refractory materials, new materials , electronic plastics, ceramics , fertilizers , metallurgy , mining, dry mortar , special building materials other sectors of the powder and solid , powder and liquid mixture . Horizontal ribbon mixer cone mixermixing efficiency is doubled.

2. Discharge device Conventional configuration of horizontal screw belt mixer: pneumatic curved flap valve. When the valve is closed, the curved flap of the valve fully fits the arc surface of the cylinder. In the mixing process, there is no redundant mixing dead angle, making the mixed materials more uniform. The following pictures are manuel discharge valve and pneumatic drive discharge butterfly valve

Contact USLaizhou Keda Chemical Machinery Merry Zhao