Paddle Stirring Structure Chicken Pig Livestock Dung Cow Dung Rotary Dryer Machine with 2-50 Tph

Basic Info

| Model NO. | 1500*15000mm |

| Material Status | Powder, Cream, Bulk |

| Drying Medium | Air |

| Operation Pressure | Atmospheric Pressure |

| Operational Method | Continuous |

| Name | Paddle Stirring Structure Chicken Pig Livestock Du |

| Keywords | Cow Dung Dryer |

| Application | Animal Dung Waste Dryer |

| Spare Parts | 1 Years |

| Raw Material Moisture | 20-80% |

| Certification | CE/ISO |

| Temperature | 600-800 |

| Transport Package | Wooden Case |

| Specification | 1800*18000MM |

| Trademark | Baoyuan |

| Origin | Henan |

| HS Code | 8419399090 |

| Production Capacity | 50 Sets/Year |

Product Description

Product Description

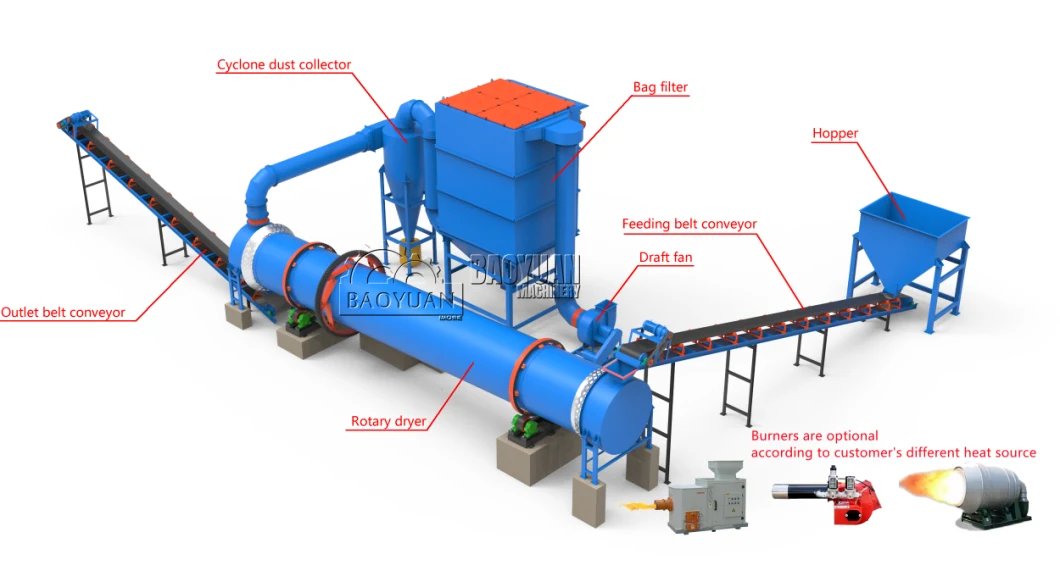

Animal Manure Dryer, also known as paddle agitated rotary drum dryer, rake roller dryer, rotary rake drum dryer, and rotary paddledrum dryer. The machine has kept the ordinary drum advantages of the dryer, it is custom designed suit to the disadvantage of the moisture is more than 50% weak stick, sticking material drying, and the drum center "black hole" phenomenon lead to the unit area evaporation capacity is inefficiency and high fuel consumption etc

1. This animal manure dryer can realize the automatic and intelligent control, the operation parameters can be automatic control,the dryer is always in the best condition to running, it can be ensure uniform drying out of the raw material moisture is stability.

2. The inside of chicken manure rotary dryer has the unique flights to hits and tumbling the materials. In order tomaximize efficiency of heat transfer between the material and drying air. The output of equipment increase more than 50% and the fuel energy consumption decrease more than 30%. 3. This machine uses four-wheel drive assembly. The driving is more stable and reliable.4.The spatial footprint of general rotary drum dryer less footprint about 40%. The civil investment reduced about 40%.The equipment cost decrease about 20%.

The dryer is suitable for chicken manure, cow dung, feces organic fertilizer, sludge, bean dregs, starch residue, sauce residue, sprayed corn kernels, cassava residue, beer distiller's grains, lees, straw, pasture and other 30-85% moisture content of material Drying. At the same time, this dryer is also suitable for wood chips, biomass, sludge, river sand, aggregates, coal, silica sand, straw, asphalt, organic fertilizer, beer residue, distiller's grains, mineral powder, etc.

Product Parameters| Type | Gradient(%) | Speed(r/min) | Inlet air temperature | Power(KW) | Production(t/h) | Weight(t) |

| 600*6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| 800*8000 | 3-5 | 3-8 | ≤ 700 | 4 | 0.8-2 | 3.5 |

| 800*10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| 1000*10000 | 3-5 | 3-8 | ≤ 700 | 5.5 | 1-3.5 | 5.6 |

| 1200*10000 | 3-5 | 3-8 | ≤ 700 | 7.5 | 1.8-5 | 14.5 |

| 1200*12000 | 3-5 | 3-8 | ≤ 700 | 11 | 2-6 | 15.8 |

| 1500*12000 | 3-5 | 2-6 | ≤ 700 | 15 | 3.5-9 | 17.8 |

| 1800*12000 | 3-5 | 2-6 | ≤ 700 | 18 | 5-12 | 25 |

| 2200*12000 | 3-5 | 2-6 | ≤ 700 | 18.5 | 6-15 | 33 |

| 2200*18000 | 3-5 | 2-6 | ≤ 700 | 22 | 10-18 | 53.8 |

| 2200*20000 | 3-5 | 2-6 | ≤ 700 | 30 | 12-20 | 56 |

| 2400*20000 | 3-5 | 2-6 | ≤ 700 | 37 | 18-30 | 60 |

| 3000*20000 | 3-5 | 2-6 | ≤ 700 | 55 | 25-35 | 78 |

| 3000*25000 | 3-5 | 2-6 | ≤ 700 | 75 | 32-40 | 104.9 |

Baoyuan Machinery is a comprehensive enterprise that comprises R& D, test, manufacture, sales and service functions. We have succeeded in researching and supplying solutions with the following equipment: Drying equipment, activated carbon production equipment, building materials equipment, beneficiation equipment, crushing equipment and other products.

With our leading-edge technologies, advanced processing equipment and our corporate spirit of "innovation, pragmatism, unity, hard work and dedication", our company has the strength to meet the challenges from all aspects. We have the confidence to build "Baoyuan" into a world-renowned brand, provide quality services for the dryer and building processing industry, and achieve a win-win situation between the company and customers.Related product