Category

Disc Type Wood Chipper for Wood Process Plant Machine

Overview Disc type Wood Chipper for wood process plant machine Product Description Introduction of Wood Chipper It is an

Basic Info

| Model NO. | 1150 |

| After-sales Service | Lifetime After-Sales |

| Type | Disc Wood Chip Machine |

| Automatic Grade | Full-Automatic |

| Warranty | 1 Year |

| Condition | New |

| Engine | 55kw |

| Shaft Speed | 600mm |

| Hourly Capacity | 8000kg |

| Blade Size | 340*150*14mm |

| Blade Qty | 4 |

| Transport Package | Iron Crate |

| Specification | 2560*1150*1800mm |

| Trademark | Yufchina |

| Origin | Henan, China (Mainland) |

| HS Code | 8465960000 |

| Production Capacity | 80 Set/Sets Per Month |

Product Description

Disc type Wood Chipper for wood process plant machineProduct Description

Introduction of Wood Chipper

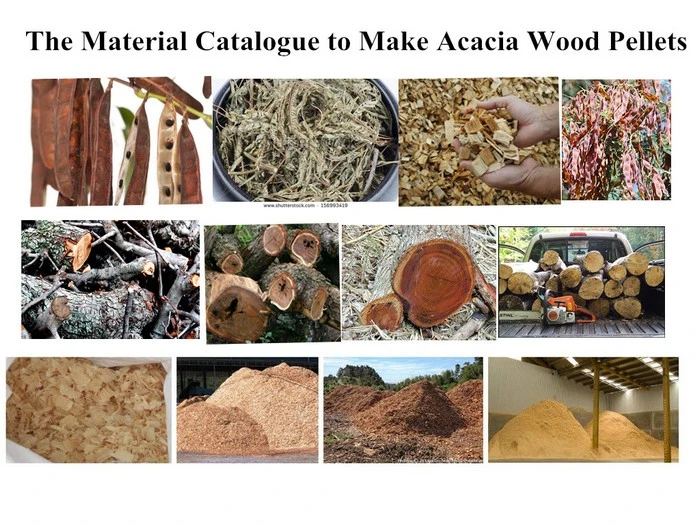

It is an ideal chipping equipment of processing chipper like wood branch, round logs, square blocks, and wood pieces into small pieces wood chips. The Wood Chipper can solve the problem of large difficult wood; The Wood Chipper can handle many raw materials like wood log, bamboo, tree branches and wood fiber rod. Disc Wood Chipping Machine is widely used in the production of paper making, edible fungus, shaving board, sawdust, high density board, fiber board and so on.

Application

Saw dust • Wood Chips • Wood logs • Tree branch • Wheat Straw • Peanut-shell • Rice husk •Sugar Cane Bagasse • Coffee Husk • Paddy Straw • Sunflower Seed Husk • Sunflower Stalk • Reeds •Cotton plant Stem • Tobacco waste • Mustard Stalk • Jute waste • Bamboo Dust • Tea waste • Palm husk • Soybeans husk and many other agro and forest wastes, which size is about 30mm.

Wood chipper machine can cut wood, branches, bamboo into small pieces, which is extensively applied in the material-preparing of pulp paper-making, OSB and MDF production and also in the individual wood chips production, different capacity we can supply, please contact for more news.

Disc Wood Chipper Features:

- Firm and reasonable structure;

- Easy to install;

- Convenient to operate and maintain;

- High production capacity;

- Final wood chip has fine quality;

- Length of the wood chips can be adjusted freely in the defined limits.

| Model | 420 | 600 | 800 | 950 | 1150 | 1410 |

| Power(kw) | 7.5 | 15-18.5 | 30 | 37 | 55 | 90 |

| Main shaft speed (r/min) | 600 | 600 | 550 | 550 | 600 | 600 |

| Hourly capacity (kg) | 500 | 1000-1500 | 3000 | 5000 | 8000 | 10000 |

| Blade size (mm) | 150*70*8 | 200*100*10 | 230*120*12 | 250*120*12 | 340*150*14 | 480*170*18 |

| Blade qty | 3 | 3 | 4 | 4 | 4 | 4 |

| Overall dimension (mm) | 1200*500*800 | 1500*570*1050 | 1850*730*1240 | 1900*820*1500 | 2560*1150*1800 | 2900*1400*2350 |

Our AdvantagesRich project experience. We've built more than 40 wood pellet product line in domestic and overseas. We can provide customized solution according to different biomass materials and customers' requirements.

After continual improvements and upgrades, we've achieved high quality and stability of our products. All our products can work continuously for 24h.

We've built an installation and commissioning team with efficient technique and rich experience. We make sure every machine delivered to customers are in the best status. We can help our customers to train eligible operators.

We have formal after-sale service system. For every customer, we have a specialized record, and a lifelong technical services representative. Solve any problems customer encounters in production.

In short, we aim to be the investment adviser for our customer. We'll design the wood pellet project according to the raw materials and market condition, and work out the best investment scheme for our clients. If you have intention to engage in biomass industry, or you have biomass wastes to deal with, welcome to contact us in the form below.

After Sales Service

Pre-sale

We adhere to the principle of acquiring maximum profit at minimum investment,while meeting the needs of each customer.During-sale

We have production progress report each week with detailed description and photos, including raw materials tables, process and deep process records, testing data sheest, etc.After-sale

Warranty period of the equipment is 1 year.During the warranty period, the damage caused by non-human factor, YUFENG will be responsible for the repair or replacement.If you have any questions, please feel free to contact us.