Commercial Forestry Machine 40hhp 8 Inch Wood Chipper Shredder

Basic Info

| Model NO. | YB-6130/YB-6145 |

| Power | 25/32/55HP Diesel Engine |

| Start-up Method | Electric Start |

| Rotation Speed of Main Machine | 2900r/Min |

| Diameter of Feed Rollers | 280mm |

| Feeding Roller Power | Hydraulic Motor |

| Diameter of Knife Roller | 300mm |

| Number of Blades | Movable Knife 3 Pieces Static Knife 1 Piece |

| Blade Length | 300mm |

| Cell Specification | 12V 105ah |

| Generator Power | 800W |

| Diesel Tank Volume | 20L |

| Hydraulic Oil Tank Volume | 25L |

| Inlet Size | 700*500mm |

| Transport Package | Packing in Wooden Boxes |

| Specification | L2300*W1300*H1800mm |

| Trademark | yuruida |

| Origin | Henan |

| Production Capacity | 800-2000h/Kg |

Product Description

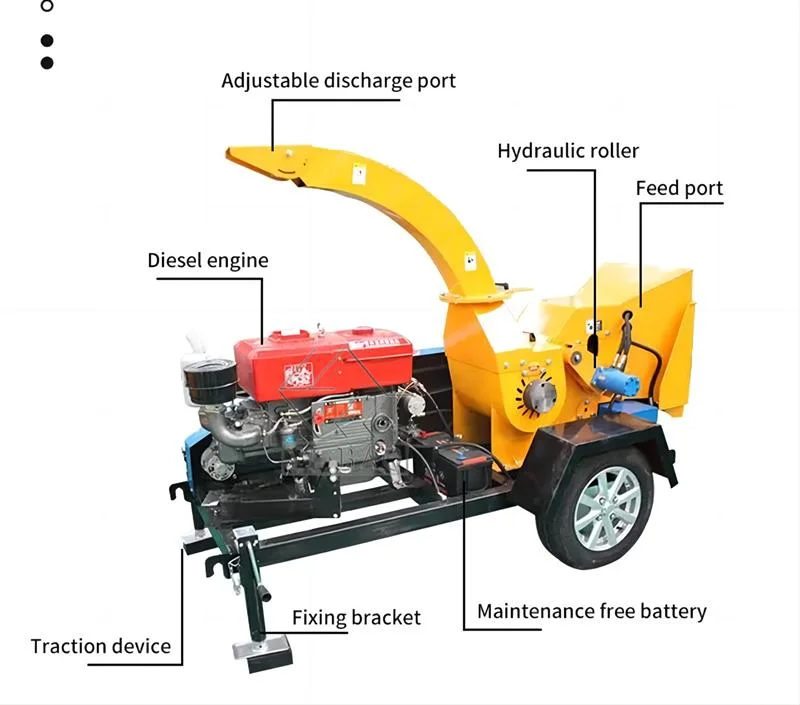

Working principle

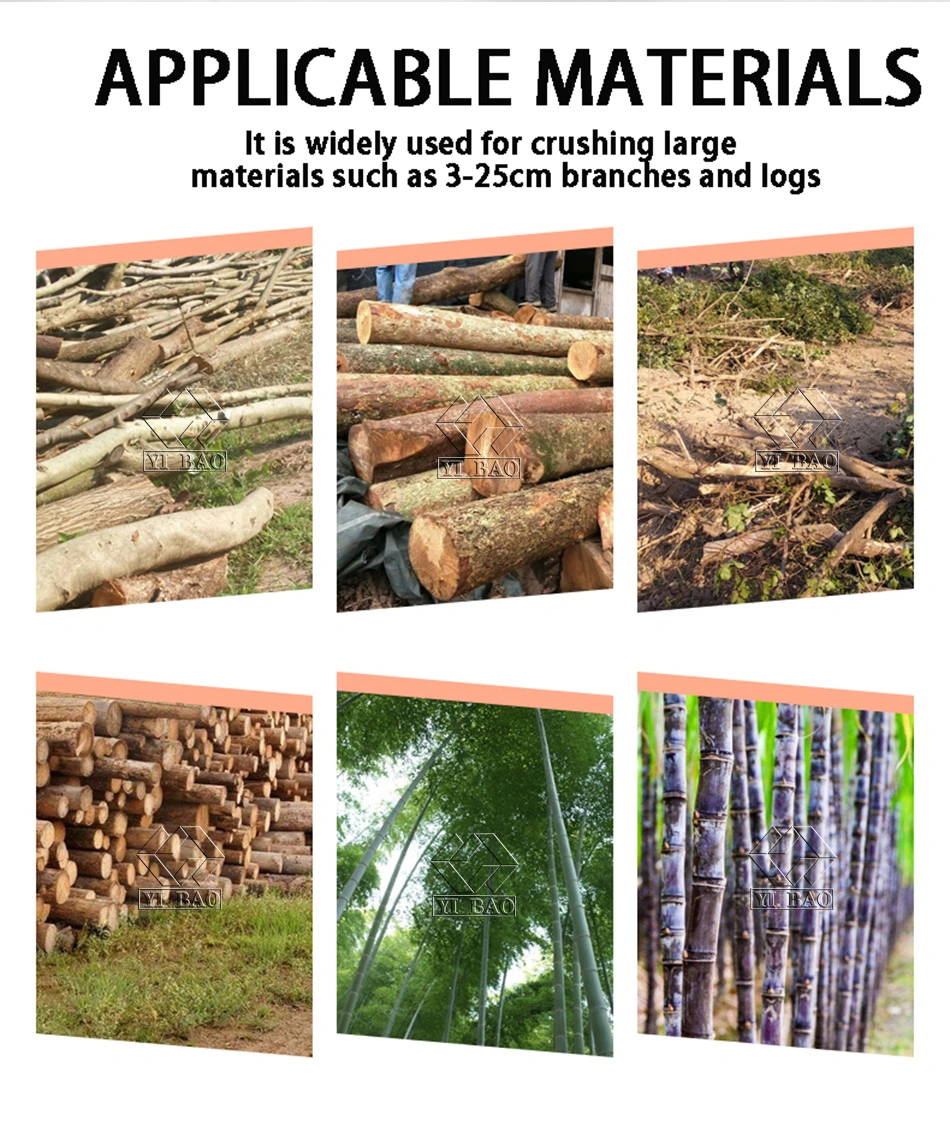

The feeding system consists of a feeding platform and a hydraulic forced feeding pressure roller, powered by a high flow hydraulic motor,which forces unevenly coarse and fine branches and twigs into the crushing chamber. The cavity is welded as a whole for durability; the knife roller is fixed in the centre of the cavity by a central shaft and powered by a diesel engine or motor through a belt. The blades are evenly attached to the knife roller and do the cutting work with the high speed rotation of the knife roller.

Product Parameters

| Model | YB-6130 | YB-6155 |

| Diesel Engine | 32P | 80P |

| Feed Size | ≤150mm | ≤250mm |

| Output | 1.0-1.5t/h | 3-5t/h |

| Size | 2400*1200*1400mm | 2600*1400*1400mm |

Finished Product

---------------------------------------------- The size of finished product can be adjusted from 5-20mm -------------------------------------------------

Packaging & Shipping

Our Team

Henan YiBao Machinery was founded in 2018,located in Zhengzhou, Henan Province, with convenient transportation, such as free ways,high-speed railways, airports, etc. We mainly produce Wood Pellet Mill machine, biomass granulator, sawdust pellet machine, Feed Pellet processing Machine, wood crusher, wood chipper, dryer and other related supporting equipment. We have introduced advanced German production technology and cooperated with many domestic universities in research and development. Now we have a research and development team of more than 20 persons to provide customers with customized various scale production lines. We have a professional sales team(35 persons). They can design and provide suitable equipment or production lines to meet the customers' actual needs. We also have young salesmen with fluent oral English to serve customers by online videos . In addition, we also have a dedicated after-sales service team(10 persons) to provide technical supports and guidance in 24 hours . Our products have been approved CE,SGS,ISO9000 etc.And they have been currently exported to Europe and North America ,Southeast Asia, Africa and other regions and countries. The quality and after-sales service makes us a good reputation in the machinery industry. We had,have,and will have been committed to protecting the environment and improving the ecosystem as our purpose and principle.!!!

Certifications

FAQ

1. Are you a trading company or manufacturer?--We are a manufacturer. We have own factory and we have specializing in manufacturing wood machinery for 30 years. 2. How about the output about this machine? --The output differs machine to machine. We have tested our machine for many times, the machine we sold can meet your demand. 3.How about the quality of your product?-- Our products manufactured strictly according to national and international standard.-- We have ISO certification.-- We take a test on every product before delivery.4.How about price of this product? -- We do quotation as soon as possible for any customer.-- Discount can be given according to quantity.5.If you can be custom-made?-- We can make products according to customer's requirements.