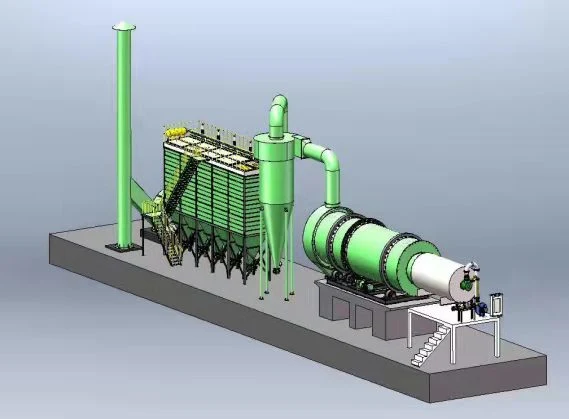

China Supplier Aggregate/Limestone/Ore Rotary Drum Dryer for Sale

Basic Info

| Model NO. | TYD-136 |

| Model | 2.2X5m |

| Object | Limestone |

| Voltage | 220V |

| Drum diameter | Φ2200mm |

| Certification | ISO9001:2000, CE, ISO9001:2008, CCC |

| Energy Saving | Energy Saving |

| Warranty | 1 Year |

| Color | Grey |

| Customized | Customized |

| Condition | New |

| After-sales Service | Installation and Technical |

| Transport Package | Standard Packing |

| Specification | 2.2X5m |

| Trademark | TYD |

| Origin | China |

| HS Code | 8419399090 |

| Production Capacity | 100PCS/Month |

Product Description

TengYiDa Rotary-drum DryerRotary-drum Dryer are widely used for building material, metallurgy, chemical industry, cement plant for dry sand, slag, clay stone, etc. Rotary drum dryer mainly consists of rotary body, raw material feeding plate,driving and supporting device

pon of TE NG YDescription of TENGYIDA Three Cylinder Dryer

IDA Three Cylinder Dry

Performance Characteristics

1. Low outlet air temperature, longer service life of dust removal equipment.

2. Sizes of lump materials, particles, and powders are less than 20mm can be dried.

3. Gear driving is not required and it's directly driven by roller, with higher mechanical efficiency.

4. Without the phenomenon of air leakage, the sealing difficulty is totally solved, and the installation can be finished within a few hours.

5. 50% of area covers has been reduced compared with the single drum dryer, and land investment reduced by 50%, power consumption reduced by 60%.

6. The self-insulation thermal efficiency of three-cylinder dryer can reach above 70% (the self-insulation thermal efficiency of traditional single drum dryer is only 35%), it has remarkable energy saving effect.

7. Final moisture indicators can be regulated easily according to the request.

8. Less than 1% of material moisture can be assured by the three-cylinder dryer, which is the preferred product for the dry mixed mortar and slag powder production line.

9. The temperature of discharged material is < 50 ºC, which can be directly conveyed into the storage silo, needless to cool down in the cooling shed.

Using alloy steel plate, wear-resisting 3-4 times than ordinary steel plate.Reducing the floor area by about 50% compared to the single-cylinder dryer.The material is 15% and the final moisture content is ensured to be 0.5-1% or less.According to user requirements can easily regulate the desired final moisture index.

ApplicationsPowder& particle: Sands,limestone,stones,clay,mineral filter cake,coal,iron sulphate,filter cakes,fly ash,gypsum etc.Damp and sticky material:Coal slime,sewage sludge,bentonite,Kaolin etc.Corrosive material: Fertilizer,animal dung,slag etc.

Features 1. International standard with ISO,CE certificate; 2. Simple system,safe and easy operation; 3. Flexibility in fuels used (NG,Oil,Coal ect.); 4. Year of experience with all types of dryers; 5. Capable of installation anywhere in the world; 6. In house engineering for custom fit applications; 7. Proven design.The structure we designed is advanced and compact. According to your site and capacity, we can provide you reasonable design with factory price. Our professional installation team has rich experience to complete the installation, commissioning fast, and also to train workers how to operate, maintain the equipment. As a professional and highly experienced manufacturer of dry mortar mixing equipment, rotary dryers and kiln, grinding mill equipment, building materials processing equipment in China for more than 20 years. We are in the leading position in this scopes.

Packaging1, HS code can be supplied to you for checking importing tax in your country.2, Standard export packaging by container, which should be applicable to international requirement.3, Big size equipment will be fixed by steel wire, while small ones together with spare parts will be packed into wooden boxes.ShippingUsually by sea, sometimes by land, air.Delivery time: 15-30 days after deposit arrived

7 x 24 h online service

1. Pre-sale services:

Act as a good adviser and assistant of clients

(1) Select equipment model;

(2) Design and manufacture products according to clients' special requirement;

(3) Train technical personnel for clients;

2.Services during the sale:

Respect clients; considering every aspect and details for our customers

(1) check products ahead of delivery;

(2)keep costumers informed about the delivery process

3. After-sale services

We promise excellent after-sale service!

(1) Assist clients to prepare for the first construction scheme;

(2) Install and debug the equipment;

(3) Train the first-line operators on site;

(4)Take initiative to eliminate the troubles rapidly at site;

(5)Provide maintenance for big items.

And other rational requirement brought up by our clients.