200L Lifting Vacuum Emulsifier Homogenizing Mixer Machine for Making Cosmetics Cream Lotion Shampoo

Basic Info

| Customized | Customized |

| Condition | New |

| Warranty | >2 Year |

| After-sales Service | Long Aftersale Service |

| Material | SUS304/316L |

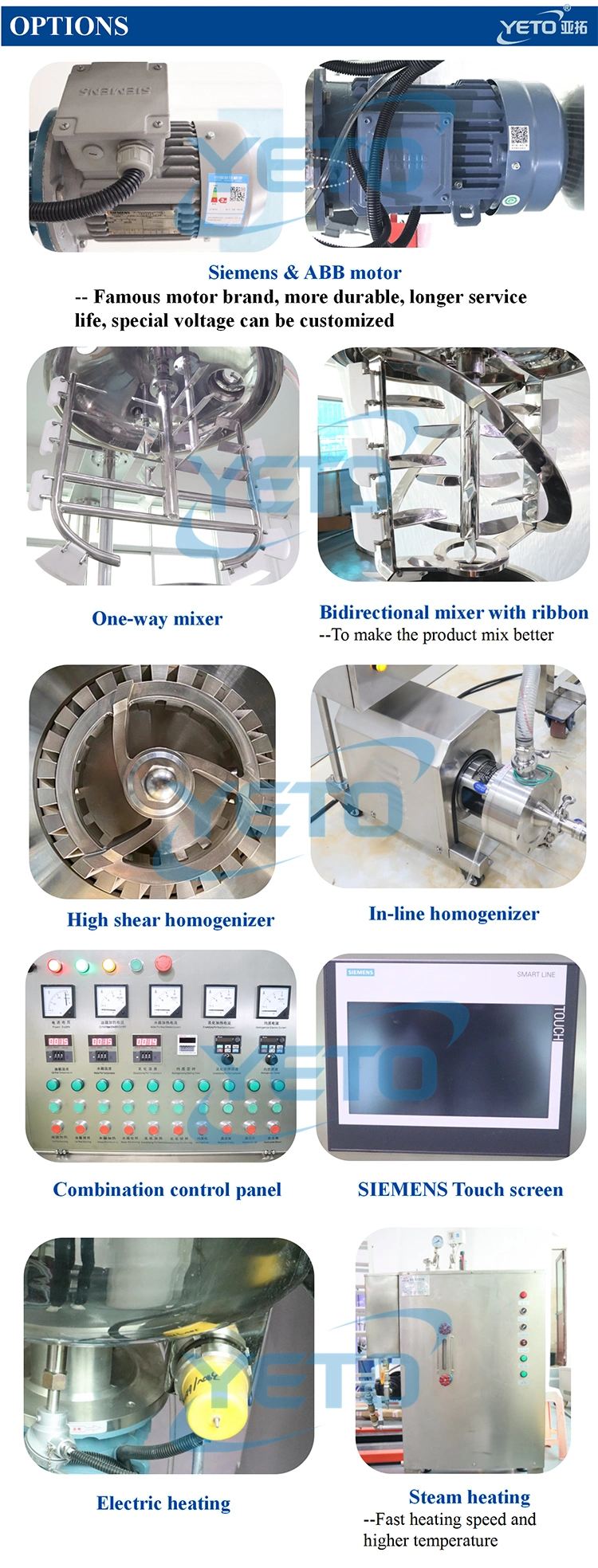

| Motor | Siemens |

| Transport Package | Wooden Case Packing |

| Specification | 50-500L |

| Trademark | YETO |

| Origin | China |

| HS Code | 8479820090 |

| Production Capacity | 20set/Month |

Product Description

What is production vacuum emulsification mixer?RS production vacuum emulsification mixer is a tilt-able vacuum emulsifying machine for the production of viscous emulsions and suspensions in the cosmetic, pharmaceutical, food and chemical industries. It's the most popular vacuum emulsification machine design in Asia and US and is suitable for making small to medium batches of cream and emulsions. What is production vacuum emulsification plant made of?RS production vacuum emulsification equipment is generally made of main emulsification blender, oil phase mixer, water phase mixer, vacuum system, hydraulic lifting system, tilting system for the main emulsifying mixer, heating and cooling system, temperature control system, electrical control panel etc. The main emulsification mixer consists of a high speed rotor stator homogenizer and counter-rotating centre agitator and wall scraper. The homogenizer, centre agitator and wall scraper are all mounted from the top of the cover. The oil and water phase mixers have exactly the same construction. There's a high speed disperser mounted from the top of the cover which helps dissolve the ingredients. Some customers will omit the oil and water phase mixers and keep the main emulsification machine only.

Parameter details

No. | Item name | Configuration and technical parameters | Remark |

1.1 | Working Capacity : | Total design capacity:600L; Working capacity :500L; | Load factor :0.8 |

1.2 | Heating method: | Jacketed steam heating; | Operating pressure: Normal pressure |

1.3 | Structure: | Three layers ,Head up and down, with flange type manhole cover with Ribbon agitation on the wall scraper stir the bottom with homogenizer; | |

1.4 | The material of the tank: | The material contact part:SUS316L;Thickness:3 mm; | Imported sheet: Finland |

Inner jacket thickness SUS304:5mm | With material certificate | ||

Shell :SUS304,thickness :2mm | Heat preservation:Aluminum silicate | ||

1.5 | Cover craft: | Material filer,Vacuum pressure gauge,Vacuum removing valve,Vacuum port,Positive pressure inlet,CIP clean ball (3 pieces),sight glass light,View window,spice inlet | No angles,the pipe fittings and valves meet the GMP requi |